Li-compressor tsa khase ea piston (li-compressor tse pheta-phetoang) li fetohile lisebelisoa tsa mantlha khatellong ea khase ea indasteri ka lebaka la tlhahiso ea tsona e phahameng haholo, taolo e bonolo, le ts'epahalo e ikhethang. Sengoliloeng sena se qaqisa ka mokhoa o hlophisehileng melemo ea bona ea tekheniki maemong a khatello ea khase ea mefuta e mengata, e ipapisitseng le melaoana ea moralo oa sebopeho.

I. Moralo oa Sebopeho sa Motheo

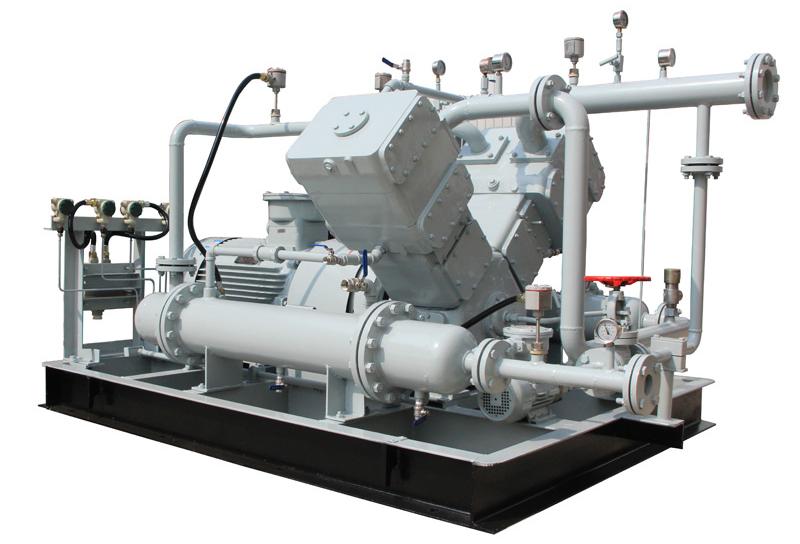

Ts'ebetso ea li-compressor tsa khase ea piston e tsoa ho sistimi e hokahaneng hantle ea likarolo, ho kenyelletsa le likarolo tse latelang tsa bohlokoa:

1. Kopano ea Cylinder ea Matla a Phahameng

E entsoe ka tšepe e entsoeng ka tšepe, tšepe ea alloy, kapa lisebelisoa tsa ho roala tse khethehileng ho mamella ho bola ha nako e telele ho tsoa ho mecha ea litaba e matla joalo ka likhase tse nang le asiti (mohlala, H₂S) le oksijene ea khatello e phahameng.

Likanale tse kopantsoeng tsa ho futhumatsa metsi / oli ho laola ka nepo ho feto-fetoha ha mocheso ho bakoang ke thepa ea khase (mohlala, viscosity e tlase ea hydrogen, reactivity e phahameng ea ammonia).

2. Kopano ea Piston ea Lintho tse ngata

Piston Crown: Khetho ea thepa e etselitsoeng k'hemistri ea khase-mohlala, 316L tšepe e sa jeleng paate bakeng sa ho hanyetsa khase e nang le sebabole, liphahlo tsa ceramic bakeng sa tikoloho ea mocheso o phahameng oa CO₂.

Sistimi ea Ring ea Tiiso: E sebelisa litiiso tsa graphite, PTFE, kapa tšepe tse kopantsoeng ho thibela ho lutla ha likhase tse nang le khatello e phahameng (mohlala, helium, methane), ho netefatsa katleho ea compression ≥92%.

3. Mokhoa o bohlale oa Valve

E lokisa ka matla nako le nako ea li-valve tsa ho tsoa le ho phahamisa ho amohela likhase tse fapaneng le likhakanyo tsa khatello (mohlala, naetrojene ho 1.5:1 ho hydrogen ho 15:1).

Li-valve tse thibelang mokhathala li mamella ho palama libaesekele tse phahameng (≥1,200 cycles/metsotso), ho eketsa nako ea ho lokisa tikolohong ea khase e tukang kapa e phatlohang.

4. Modular Compression Unit

E ts'ehetsa litlhophiso tse feto-fetohang tsa 2- ho isa ho 6-mohato oa khatello, ka khatello ea mohato o le mong ho fihla ho 40-250 bar, ho fihlela litlhoko tse fapaneng ho tloha polokelong ea khase ea inert (mohlala, argon) ho ea ho khatello ea syngas (mohlala, CO + H₂).

Likhokahano tse hokahanyang ka potlako li etsa hore ho be le liphetoho tse potlakileng tsa sistimi e pholileng ho latela mofuta oa khase (mohlala, ho pholisa metsi bakeng sa acetylene, ho pholisa oli bakeng sa Freon).

II. Melemo ea ho lumellana ha khase ea indasteri

1. Tšebelisano e Feletseng ea Media

Ligase tse Corrosiveng: Lisebelisoa tse ntlafalitsoeng (mohlala, li-cylinders tsa Hastelloy, lithupa tsa titanium alloy piston) le ho thatafatsa bokaholimo li netefatsa ho tšoarella tikolohong e ruileng ea sebabole le halogen.

Likhase tse Hloekileng ka ho Fetisisa: Lubrication e se nang oli le tlhoekiso e nepahetseng haholo e fihlela bohloeki ba ISO 8573-1 Sehlopha sa 0 bakeng sa naetrojene ea boemo ba elektroniki le oksijene ea bongaka.

Ligase tse Tletseng Molelo/Ho Phanyeha: E tsamaellana le litifikeiti tsa ATEX/IECEx, tse nang le khatello ea spark le li-dampers tse feto-fetohang tsa khatello bakeng sa ho tšoara haedrojene, oksijene, CNG le LPG ka mokhoa o sireletsehileng.

2. Matla a Ts'ebetso a Adaptive

Wide Flow Range: Li-drive-frequency drives le clearance volume control li nolofalletsa taolo ea phallo ea mola (30% -100%), e loketseng tlhahiso ea nakoana (mohlala, phepelo e tsoelang pele ea phepelo ea limela) le phepelo e tsoelang pele (mohlala, likarolo tsa karohano ea moea).

Taolo e Bohlale: Lisensara tse kopaneng tsa khase tse ikamahanyang le maemo (mohlala, menyako ea mocheso, likhahla tsa lubrication) ho thibela ho se sebetse hantle ho bakoang ke liphetoho tsa tšohanyetso tsa thepa ea khase.

3. Lifecycle Cost Effective

Moralo oa Tlhokomelo e Tlase: Nako ea bophelo ea karolo ea bohlokoa e atolosoa ka > 50% (mohlala, linako tsa ho lokisa crankshaft ea lihora tse 100,000), ho fokotsa nako ea ho phomola libakeng tse kotsi.

Ntlafatso ea Matla: Likhatello tsa ho hatella tse etselitsoeng li-indices tsa adiabatic tse khethehileng ka khase (k-values) li finyella 15% -30% ea ho boloka matla ha ho bapisoa le mefuta e tloaelehileng. Mehlala e kenyelletsa:

Moea o hatelitsoeng: Matla a khethehileng ≤5.2 kW/(m³/min)

Ho matlafatsa khase ea tlhaho: Ho sebetsa hantle ha Isothermal ≥75%

III. Lisebelisoa tsa bohlokoa tsa indasteri

1. Ligase tse Tloaelehileng tsa Indasteri (Oksijene/Nitrogen/Argon)

Tlhahisong ea tšepe ea tšepe le ea semiconductor, meralo e se nang oli e nang le sieve ka mor'a kalafo ea limolek'hule e netefatsa bohloeki ba 99.999% bakeng sa lits'ebetso tse kang ts'ireletso ea tšepe e qhibilihisitsoeng le masela a liphaphatha.

2. Ligase tsa Matla (Hydrogen/Syngas)

Khatello ea mekhahlelo e mengata (ho fihla ho 300 bar) e kopantsoeng le lisebelisoa tsa khatello ea ho phatloha ka mokhoa o sireletsehileng o tšoara hydrogen le carbon monoxide polokelong ea matla le motsoako oa lik'hemik'hale.

3. Ligase tse Corrosive (CO₂/H₂S)

Litharollo tse ikamahanyang le ho bola—mohlala, lilakane tsa tungsten carbide le mafura a hananang le asiti—li sebetsana le maemo a mangata a sebabole, a mongobo o phahameng sebakeng sa oli le ho nkeloa khabone.

4. Likhase tse Ikhethang tsa Elektroniki (Metsoako e Fluorinated)

Kaho e tiileng le ho lemoha ho lutla ha helium mass-spectrometer (sekhahla se lutlang <1×10⁻⁶ Pa·m³/s) e netefatsa ts'ebetso e bolokehileng ea likhase tse kotsi joalo ka tungsten hexafluoride (WF₆) le nitrogen trifluoride (NF₃) ho liindasteri tsa photovoltaic le IC.

IV. Tsoelo-pele e Ncha ea Theknoloji

Digital Twin Systems: Mohlala oa nako ea sebele oa data o bolela esale pele ho roaloa ha lesale la piston le ho hlōleha ha valve, ho nolofalletsa litlhokomeliso tsa tlhokomelo likhoeli tse 3-6 esale pele.

Kopano ea Mokhoa o Motala: Litsi tsa ho khutlisa mocheso oa litšila li fetolela 70% ea mocheso oa khatello hore e be mouoane kapa motlakase, e ts'ehetsa lipakane tsa ho se nke lehlakore tsa khabone.

Liphetoho tse matla tsa khatello e phahameng: Theknoloji ea cylinder e hatelitsoeng esale pele e fihlela khatello ea mohato o le mong> 600 bar litlhophisong tsa lab, e bula tsela bakeng sa polokelo ea haedrojene le lipalangoang nakong e tlang.

Qetello

Li-compressor tsa khase ea piston, ka meralo ea tsona ea modular le bokhoni ba ho e etsa, li fana ka tharollo e tšepahalang bakeng sa ts'ebetso ea khase ea indasteri. Ho tloha khatellong ea tloaelo ho isa ho ts'ebetso ea khase e maemong a feteletseng, ntlafatso ea sebopeho e netefatsa ts'ebetso e bolokehileng, e sebetsang hantle le e baballang chelete e ngata.

Bakeng sa litataiso tsa khetho ea compressor kapa litlaleho tsa netefatso ea tekheniki tse etselitsoeng mecha ea litaba ea khase, ka kopo ikopanye le sehlopha sa rona sa boenjiniere.

Lintlha tsa Tekheniki:

Lintlha tse nkiloeng ho ISO 1217, API 618, le litekanyetso tse ling tsa tlhahlobo ea machaba.

Ts'ebetso ea 'nete e ka fapana hanyane ho latela sebopeho sa khase le maemo a tikoloho.

Litlhophiso tsa lisebelisoa li tlameha ho lumellana le melao ea tšireletso ea lehae bakeng sa lisebelisoa tse khethehileng.

Nako ea poso: May-10-2025